About

Find Out More About Us

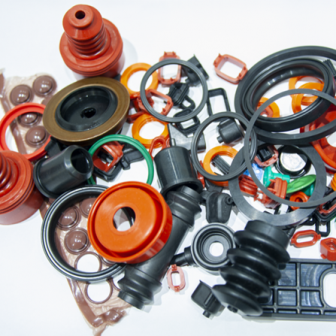

3B Auto Components Pvt. Ltd. incorporated in 2012. We have been Manufacturing of various types of Molded Rubber Components, Extruded Rubber Components and Rubber to Metal bonded items in synthetic rubber as well as natural rubber.3B has got the expertise in molding the polymers like EPDM, Nitrile(NBR), Silicon, Fluro Silicon, Viton(FKM),Polyacrylic (ACM), Vamac (AEM), Butyl, Neoprene, SBR and Natural Rubber.

We have a modernized manufacturing plant equipped with machinery that guarantees precision moulded rubber components, which are widely used in various industrial applications..

Our comprehensive product Range of Oil seals, Gaskets, Hoses, Rubber Seals, Boots, Flexible Coupling, Rubber Bumpers, Bellows, Anti Vibration Mountings, Tortional Vibration Damper, Silicon Plugs, Viton, Neoprene and Silicon parts etc. allows our clients to have a technological solution, which is precisely tailored to their manufacturing requirements. Our company is crystallization with a vision to innovate precision engineered rubber mounting, which offers complete satisfaction to our esteemed customer with customized and value-added products.These automotive rubber components, industrial rubber components, industrial rubber hose and other rubber components/ rubber parts are made with the high quality rubber and allied raw materials.

-

Vision

Profitable growth through superior customer service, innovation, quality and commitment

-

Mission

To expand and continually improve utilizing quality practices and employee involvement to manufacture or fabricate full proof quality product, for the production manufacturing industry, both in the domestic and international markets, that result in customer and employee satisfaction

Mr. M. D. Sudhakar

Founder, Chairman & Managing Director

Mr. M. D. Sudhakar, co-founder of 3B Auto Components Pvt. Ltd., is Chairman & Managing Director since The inception of 3BAC in 2012. He started 3B ENGINEERING SERVICECS along with his Brother Mr. Rohitkumar D. Sudhakar & Mr. B. D. Petakar. 3B board of Directors are reporting to Mr. M. D. Sudhakar & he is concentrating on the technical aspects of the organization in terms of product introduction / tooling and technological up-gradation across the group. He has widely travelled and keeps abreast of the latest developments in the industry through magazines seminar and trade fairs both domestic as well as abroad. He has expanded 3BAC from a start up enterprise to one of the leading manufacturer, supplier and exporter of Rubber Components in India. A visionary par excellence whose charismatic leadership is a striking quality. He believes in continual innovation, creativity and hardwork. According to him companies must transform operations so that their products, quality and service are second to none, and this must be done at a pace faster than lightening.

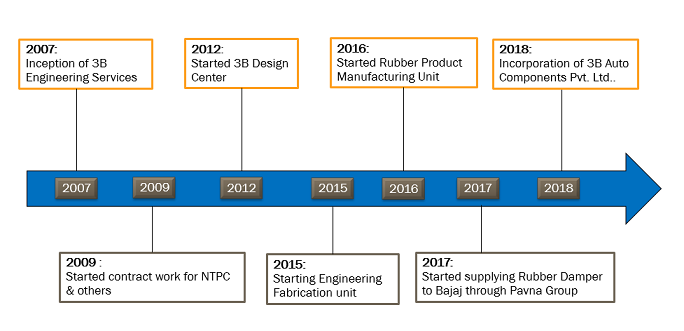

Company History

Go through Company History

Quality Policy

Look at our Company Quality policy

.png)

"We 3B AUTO COMPONENTS Pvt. Ltd. is committed to enhance the customer satisfaction by manufacturing, supplying and providing service for the products and fulfilling their requirements of quality, timely delivery and competitive price.

we shall be sensitive to the needs of our customers and shall strive to exceed their expectations. We shall train, motivate and involve our employees to continually improve their effectiveness, and that of our quality management system as well.

we shall ensure all our work processes are carried out in a safe manner without any harm to personnel or property. we shall maintain ethical business practices and create a mutually beneficial relationship with our business partner’s."

Plant Location

Check out Plant Locations

Unit-I

Plot No. 37, Swami Vivekanand Co-Operative Industrial Estate Handewadi Road, Satav Nagar, Hadapsar, Pune-411028, Maharashtra, India.

Phone no:9922464603

Unit-II

Gat No.162/B, Tower Line Road Triveni Nagar Talwade, Taluka Haveli, Pune-412114.

Phone no:9922464603

Ware House

D-1 Block, 20/6, MIDC Chinchwad Pune-411019.

Phone no:9922464603

Awards

Take a look at Company Awards

Products

Explore our Products

The rubber is of good quality, though, owing to the method of preparation adopted, the product is often impure and discoloured, and consequently usually brings a lower price than the best rubber of commerce.

- All

- O-Ring

- Oil Seals

- Gasket

Rubber O-Ring

Product Description

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable and have simple mounting requirements.

Rubber Sealing Ring

Product Description

3BAC produces two types of the sealing ring: the static sealing ring and the dynamic sealing ring.

The static sealing ring lives up to its name because it does not move, except when pulsation is caused by cycle pressure. Sealing rings which are subjected to movement are the dynamic sealing rings. ACM PolyAcrylate, Aflas®, EPDM, Fluorsilicone / FVMQ, High Purity compounds, HNBR / X-NBR, Kalrez® / FFKM, Neoprene / CR, Nitrile / NBR, SBR, Silicone / VMQ, Viton® / FKM

All sealing rings are produced to the 3BAC material specification standards.

Rubber Gasket

Product Description

GASKET is a mechanical seal that is used primarily to prevent leaks of gas or liquid, but can be used as a barrier between two objects, such as two metals or chemicals.

Rubber Groomet

Product Description

GROMMETS made of rubber or other elastic material They were widely used for mounting shock-sensitive parts particularly in equipment subject to vibration or jarring, are also used to minimize the transmission of vibration.

Oil Seals

Product Description

Oil Seal is a device that is used to prevent the leakage of lubricating oil in mechanical equipment by closing the spaces between the moving and stationary components of the equipment. Oil seals are also used in precision bearings to maintain lubricants in the bearings and prevent corrosive moisture from entering the bearings. Oil seals are also known as rubber oil seals, oil gaskets or dirt seals

Oil seals come in various sizes depending on the equipment capacity. These seals fit on various valves, pipes and any other openings where the leakage of lubricating oil needs to be prevented. The seals are used to perform two important roles, i.e., to hold the oil in place and help in lubricating the machine’s moving parts by ensuring there is no lubricant leakage. Oil seals also ensure that harmful contaminants do not let it leak in various parts of the equipment.

Rubber to Metal Bonded

Product Description

Rubber to metal bonding offers manufacturers a way to create more complex parts, both small and large, for applications in a wide variety of industries. Common applications include vibration dampening, shock absorbance, sealing, friction dissipation, noise isolation, comfort gripping, and more. Usually, the types of metal-rubber products fabricated through this process are used for applications in industries including aerospace, automotive, construction, electrical, industrial machinery, medical, plumbing, rubber rolling, and vibration absorbers.

The process of rubber bonding involves three main components: The metal substrate, the rubber material, and the bonding agents.

Customized Molded Rubber Seals

Product Description

Rubber to metal bonding offers manufacturers a way to create more complex parts, both small and large, for applications in a wide variety of industries. Common applications include vibration dampening, shock absorbance, sealing, friction dissipation, noise isolation, comfort gripping, and more. Usually, the types of metal-rubber products fabricated through this process are used for applications in industries including aerospace, automotive, construction, electrical, industrial machinery, medical, plumbing, rubber rolling, and vibration absorbers.

The process of rubber bonding involves three main components: The metal substrate, the rubber material, and the bonding agents.

IT Services

Check out IT Services

Website Development

Having a website means customers are always able to find you – anytime, anywhere. Even outside of business hours, your website continues to find and secure new customers. It offers the user convenience as they can access the information they need in the comfort of their own home, with no added pressure to buy.

So, to know more get connected with us.

Chatbot Development

A chatbot is an automated online communication tool through which the user can receive an immediate response, instead of waiting or searching through the website.Through machine learning and training, the chatbot is continually improved. It makes your business more accessible to customers, employees, members or users, 24 hours a day.

We offer customizable AI-solutions that comprise of Chatbot. Our Digital Employees handle repetitive tasks through Intelligent Process Automation.

PWA Development

A progressive web application is a type of application software delivered through the web, built using common web technologies including HTML, CSS and JavaScript. It is intended to work on any platform that uses a standards-compliant browser, including both desktop and mobile devices.

We offer a wide range of Progressive Web App Development services starting right from converting a basic web site into a light weight and extremely fast mobile application.

React Native Development

React Native is an open-source UI software framework created by Facebook, Inc. It is used to develop applications for Android, Android TV, iOS, macOS, tvOS, Web, Windows and UWP by enabling developers to use the React framework along with native platform capabilities.

Which means you don't need separate apps for iOS and Android, an React Native app will do the work on both leading OS platform.We Offer cost effective react native cross platform app development.

Enterprise Resource Planning

Enterprise resource planning (ERP) refers to a type of software that organizations use to manage day-to-day business activities such as accounting, procurement, project management, risk management and compliance, and supply chain operations.

ERP software can integrate all of the processes needed to run a company. Some benefits of ERP include the free flow of communication between business areas, a single source of information, and accurate, real-time data reporting. Contact us for more info.

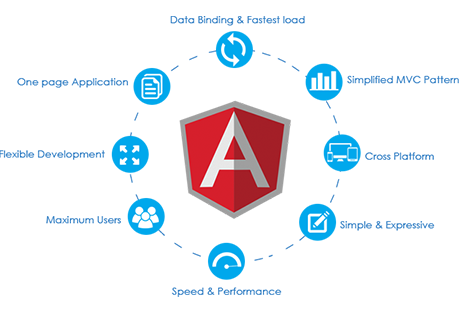

Angular Development

Angular is a platform for building mobile and desktop web applications. Angular applications helps us to achieve the maximum speed possible on the Web Platform today, and take it further, via Web Workers and server-side rendering. With Angular Build features quickly with simple, declarative templates. Extend the template language with your own components and use a wide array of existing components.

Infrastructure

Take a look at our Infrastructure

Facilities

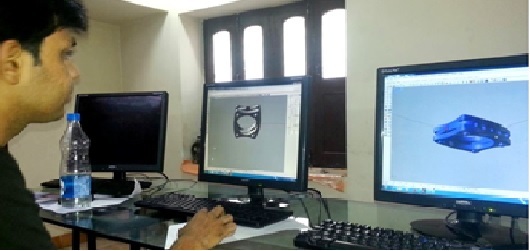

Design Development

The Company has the backing of a very strong R & D center and test lab in Pune City consisting of professionals qualified in Rubber Technology & Engineering & Validation Research with state of the art Software & Hardware for Design & simulation.Our Technocrats in R& D dept is continuously striving for new product development, improvement in existing products , Formulations for new rubber materials, cost reductions and import substitution of Automotive Parts and Components by adopting advanced technology and designing capabilities.

Rubber Mixing

The most critical process in rubber product manufacturing is mixing process. 3BAC has got the strong know-how on formulations & Mixing Technology which is acquired by the company over a period of time. The mixing is done by using dispersion Kneader and open roll mixing mill technology. The Dispersion Analyzer will ensure the quality of carbon dispersion in the mixing process. We are processing all type of synthetic rubbers & Natural Rubber in our mixing plant. We can design & develop any international customer specifications for Rubber compounds. 3BAC has installed mixing capacity of 500 MT /annum.

Rubber Molding

We have been producing different type of rubber molded components in synthetic rubber as well as natural rubber. 3BAC has got the expertise in molding the polymers like EPDM, NBR, NEOPRENE, SILICONE, FLURO SILICON, VITON(FKM) , ACM, AEM(VAMAC) , SBR, NATURAL RUBBER. We do produce molded parts by using compression molding, transfer molding and rubber injection molding process. In injection process we can do cold rubber as well as hot rubber technology to save material and increase productivity.

Laboratory & Testing Equipments

3BAC has got well equipped laboratory in the production plants. Also, we have a centralized R&D at our Plant-I at Pune & also for the validation of Raw materials & End products we are collaborated with NABL acredited lab. We have a range of equipment installed in-house which ensures the right quality products as per the customer specifications & performance requirements. We have well qualified and experienced technical staff at R&D Centre and respective production plants and the systems are synchronized in such a way that information are shared quick as possible to fix technical concerns from each plants.

Plant & Machinery

Our manufacturing unit is spread over a wide area of 3000 sq. feet, which fulfills all the requisite requirements of clients in the manufacturing process.In addition to well-equipped infrastructural set-up, we have a godown premise with sufficient storage space for inventory and finished products.

| No. | Our manufacturing consists of various hi-tech machines. |

|---|---|

| 1Nos | Hydraulic moulding machine (500mm x 500 mm ) |

| 3Nos | Hydraulic moulding machine (400mm x 400 mm ) |

| 4Nos | Hydraulic moulding machine (350mm x 350 mm ) |

| 4Nos | Hydraulic moulding machine (300mmx 300 mm ) |

| 1Nos | Horizontal plastic moulding machine ( 130 ton cap.) |

| 1Nos | Plastic hand moulding machine (WT . 20 gm ) |

| 1Nos | Plastic hand moulding machine ( WT. 28 gm ) |

| 1Nos | Finishing grinder (1.5 HP ) |

| 1Nos | Finishing buffing grinder (2 HP ) |

| 3Nos | Hand Grinder (4 inch ) |

| 1Nos | Compressor ( 5 hp Capacity ) |

| 1Nos | Mixing mill (size 12x30) |

Clients

Our Clients

Why 3BACPL

Check our Key Services

"Core Competencies(CC) in low cost Rubber Technology & automotive rubber component manufacturing"

"Innovation through constant Research & Development"

"Customer Focused operational management approach. & Complete customer satisfaction."

" Competitive pricing, Cost effective, and quick development time frame to suit our customer requirements"

"Key Account Management culture in Product development, Business development & Sales functions"

"Low, Medium & high volume production experience"

Contact

Contact Us

Email us with any questions or inquiries or call. We would be happy to answer your questions and set up a meeting with you.

Our Address

P No 37,S No 54, Handewadi Road Swami Vivekanand Industrial,Hadpasar,Pune MH411028 Maharastra.

Email Us

3BAutoComponents@gmail.com

Call Us

+91 9922464603